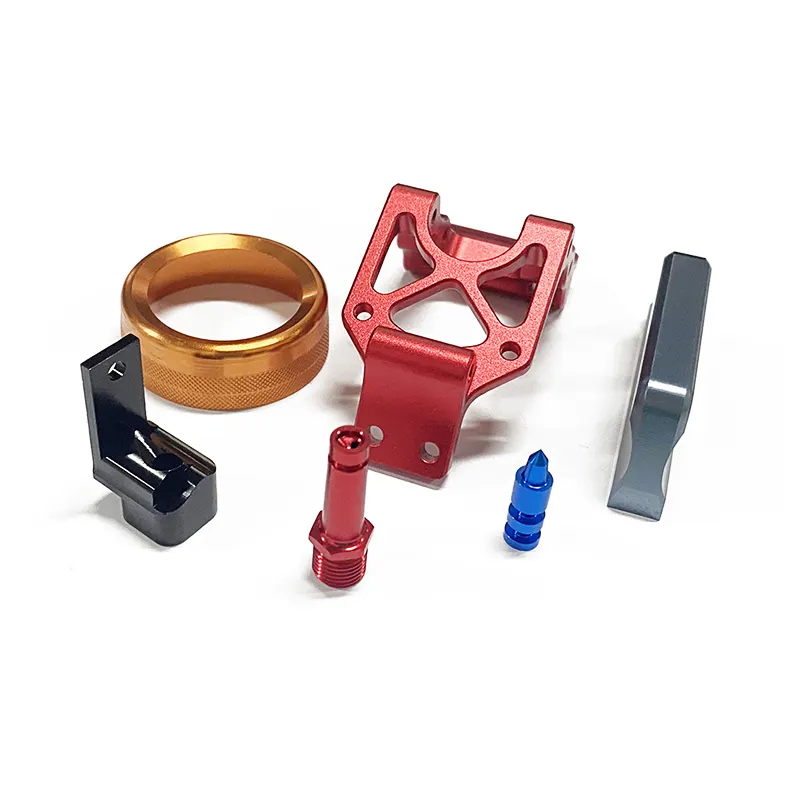

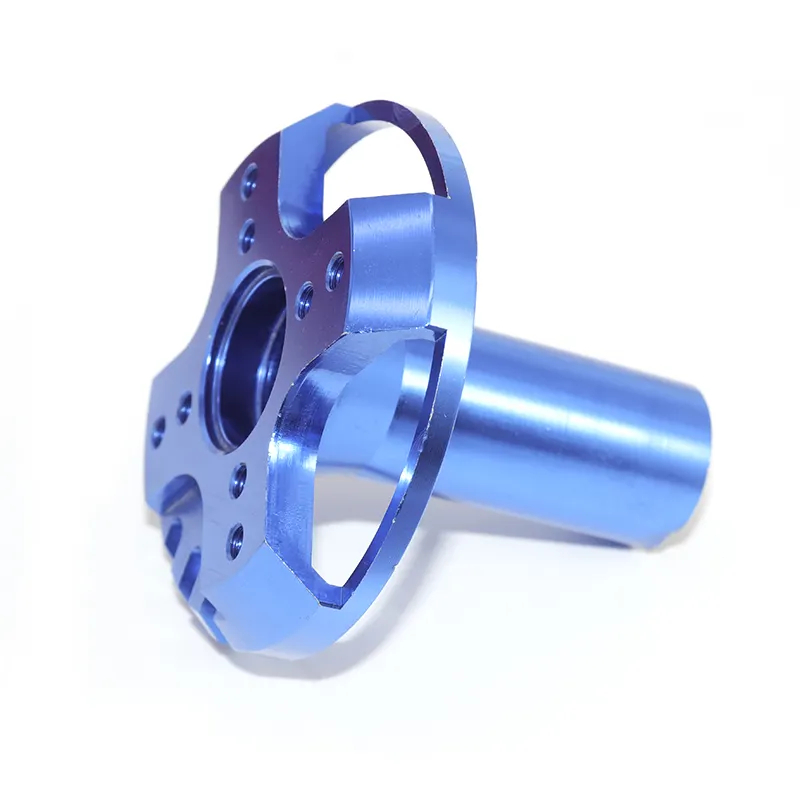

OEM Precisition Cnc Services Tšebeletso ea likarolo

Ts'ebeletso ea mochini oa CNC

▪ ▪ CNC Elnur, CNC eanya ea CNING, Turn-mill Command.

▪ Tharollo ea ho emisa ho emisa con ho na le mochini.

▪ OEM ea ntlo, likarolo tse lahlela, likarolo tse nang le mechine, likarolo tsa cnc, li-prototypes.

▪ Moetlong o phahameng oa ho phela.

▪ Mofani oa boleng bo holimo oa CNC.

▪ Talima: Logo e hlophisitsoeng, e hlophisitsoeng e hlophisitsoeng, ho beoa ka mokhoa o hlophisitsoeng.

Thepa: The tšepe ea tšepe, aluminium, carbon tšepe, koporo, Brass, Steel Alloy, Titanium enc.

| Karolo e phahameng ea pele e phahameng ea OEM CNIT likarolo tsa mochini oa mochini oa | |

| Tshebeletso | Cnc Geneng, CNCing, Laser a seha, ho khumama, ho cheka, ho kuta, ho kuta mohala |

| Lisebelisoa | Aluminium: 20002, letoto la 6000, lerang-7775, 5052, jj. |

| Tšepe e se nang thuso: Sus303, Sis304, SS316, SS316L, 17-4ph30, 17-4ph. | |

| Tšepe: 1214L / 1215/1045/4140 / SCM440 / Penm440 / 40CRME, JOTC. | |

| Brass: 260, C360, H59, H59, H60, H60, H63, H65, H68, H70, Bronze, koporo | |

| Titanium: Kereiti | |

| Phekolo ea holimo | Anodize, Bead e ne e le ea Chesoang, Screen Screen |

| Ho mamella | +/- 0.002 ~ +/- 0,.005mm |

| Bokhabane | Min ra0.1 ~ 3.2 |

| Ho taka | STP, mohato, igs, xff, ho reka ka koloi (dxf, dwg), Pdf kapa sampole |

| Lead time | Libeke tse 1-2 tsa disampole, tse 3-4 bakeng sa tlhahiso e kholo |

| Netefaletso ea boleng | Iso9001: 2015, Iso13485: 2016, SGS, SGS, SGS, SGS, SGHS, Tuv |

| Lipehelo tsa Tefo | TT / PayPal / Westunionon |

OEM CNY MANDING TEPCING PUSELETSO E TSOANG PELE EA BOTSOALLE BA LESOTHO

OEM CNY MANERING SUPS PUS POS POKS LE LITLHAKISO TSE KHOLO

Ho paka ha sehlahisoa

LBH

1. Cnc ho na le mechini efe?

Cnc Ho latela setšoantšo, CNC ho sebelisa lisebelisoa tse fapaneng ho khaola thepa e tala ka mananeo a mabeli.

2. Mosebetsi oa ka o ka Rua Molemong oa CNC?

Ha ho bapitoe ka litsela tse ling tsa ho etsa lintho, CNC ho na le ho kopana ha lisebelisoa bakeng sa thepa, boholo, tlhahiso e tlase haholo. Ho tiisa ka ho hlaka botsitso, ho nepahala, le ho mamella ka tieo.

3. Nka fumana qotsulo joang?

Litšoantšo tse qaqileng (PDF / mohato / igs / dwg ...) ka tlhaiso-leseling ea kalafo.

4. Na nka fumana qotsulo ntle le litšoantšo?

Ka sebele, re leboha ho amohela mehlala ea hau, litšoantšo kapa ho fana ka lintlha tse qaqileng tse ngata bakeng sa mantsoe a nepahetseng.

5. Na litšoantšo tsa ka li tla busoa haeba u rua molemo?

Che, re ela hloko haholo ho sireletsa boinotšing ba bareki ba litšoantšiso tsa bareki, re saena le ho amoheloa hape haeba ho hlokahala.

6. Na o ka fana ka disampole pele ho tlhahiso e ngata?

Ehlile, ho hlokahala chelete e hlokoang, e tla khutlisoa ha tlhahiso e boima e sa khonehe.

7. Ho thoe'ng ka nako e etellang pele?

Ka kakaretso, libeke tse 1-2 bakeng sa disampole, tse 3-4 bakeng sa tlhahiso e kholo.

8. U laola boleng ba boleng bofe?

.

(2) tlhahiso ea tlhahlobo ea pele - ho netefatsa boemo bo tebileng ba tlhahiso e ngata.

.

(4) Tlhahlobo ea pele ho thepa - 100% e hlahlojoa ke lithuso tsa QC pele ho romelloa.

9. U tla etsa eng haeba re fumana likarolo tse sa boleng ba boleng?

Ka kopo re romelle litšoantšo, baenjinie ba rona ba tla fumana tharollo le ho ba khutlisa bakeng sa hau.