Tharollo e Ntlehali

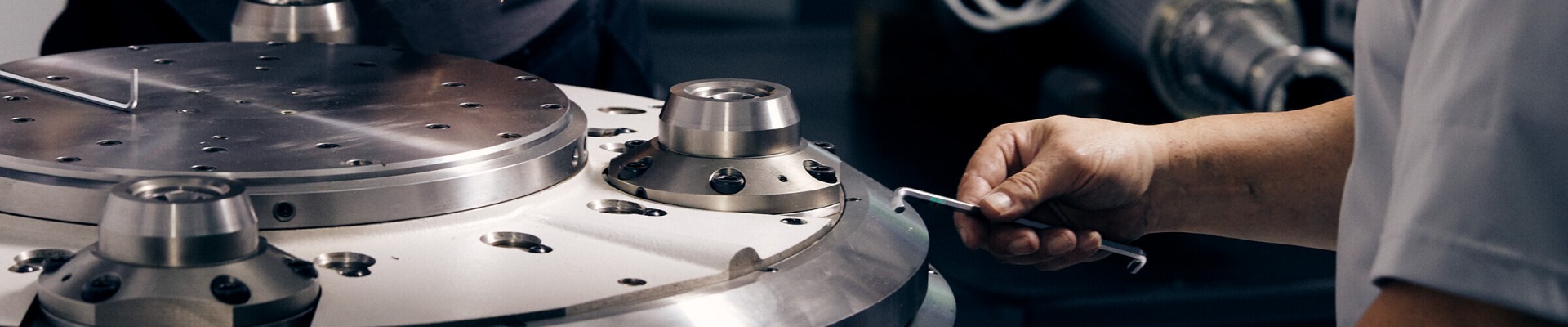

Hyluo e fana ka litšebeletso tsa boleng bo holimo tsa CN tse nang le mathata ka ho mamella. Re na le bokhoni bo boholo ba ho ipehela liperehong tse akaretsang ho etsa hore ho be le ponaletso ea CN. Marang-rang a rona a lefats'e la ho etsa tlhahiso ea balekane le sebetsa ka thepa e ngata le ho latela melao ea boleng bo holimo. Re khona ho tsamaisa morero oohle, ho tloha ponong, le ka har'a k'hamphani ea rona, hammoho le li-crete ea hona joale ea ISO 9949 ho netefatsa boleng bo ikhethang.

Litsebi tsa rona tsa litsebi tsa rona tsa litsebi tsa rona le tse shebiloeng ka taolo ea boleng li tiisa likarolo tse tšepahalang, tse nepahetseng bakeng sa lits'ebetso tse fapaneng. ho kenyelletsa:Aerospace, Medical,Oli le khase,Likoloi,Lisebelisoa tsa motlakasemmeKhoebojj.'me ba rorisoa haholo ke bareki.

Re etsa qeto ea ho iphetola ha boleng ba boleng,. Re u khothalletsa hore u ikopanye le baenjiniere ba rona 'me re ba lumelle hore ba thuse ka litlhoko tsa hau tsa morao-rao tsa tlhahiso.

Lintlha tse 4 li bontša hore mochini oa mabelo a Hyluo o lokeloa ke tumelo ea hau

1. TLHOKOMELISO

Thetso le kopano ea likarolo tsa likarolo tse entsoeng ka moetlo ke tsona feela khoebong ea rona mme ke eona eo re ikemiselitseng ho sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re sebetsa hantle, e lula re etsa bareki bohle. Ha ho mohla re 're tlose mahlo a rona bolo "mabapi le ho mamela moreki oa rona' me ha re nahana ka ts'ebeletso ea rona ea 100% le ho ela hloko litlhoko tsa bona.

2. Ho fapanyetsana

Hyluo, re sebelisa CNC 3, 4, le li-cent tsa cnc tsa li-cnc tsa li-cnc tsa Arc

Re boetse re na le bokhoni bo ikhethang ba cnc machining ea mechini e ikhethang Ka lisebelisoa tse fumanehang tsa lisebelisoa tse fumanehang le bokhoni ba 3D, re ka sebetsana le litlhoko tsa mochini bakeng sa mosebetsi o mong le o mong, ho sa tsotelehe hore na o rarahane hakae kapa o rarahane hakae.

Rona likarolo tsa mochini o sebelisa libaka tse ngata tsa Bar, ho tloha matlong a bonolo joalo ka aluminium le koporo ho ea li-titanium le cobalt-coubatt Ntle le moo, ho qheleloa ka mochini, re tšoarela, lithole tsa litho tsa bo-bong tse thata, le graphite. Mekhoa ea rona ea tlhahlobo e kenyelletsa cmm, kopanya phaello, tekanyo ea video, nDT, ho lekola le ho hlahlojoa le ho hlahlojoa le ho hlahlojoa.

Joaloka Mohloli oa Thibelo e Tletseng Bakeng sa Mehloli e Tletseng, Re etsa mesebetsi e mengata ea mocheso e kang kalafo ea mocheso, joalo, kalafo le ho kenella. Ka mananeo a rona a hlokometsoeng a mochini oa boiketsetso, re netefatsa hore likarolo li fumaneha ka har'a thepa ea nako e sa tsoaheng.

3. Boinehelo

- phetisetso e sebetsang haholo

Re ikhohomosa ka ho etsa sohle se matleng a rona ho bareki bohle ba rona. Ho tsoa ts'ebetsong e hlokolosi le ho tiisa le ho qala tlhahlobo ea hau le ea pele, re batla ho etsa bonnete ba hore likarolo tsa hau li etsoa ka tsela eo u e batlang ka eona ha u e hloka, nako le nako! Hyluo, re nka hore taelo e 'ngoe le e' ngoe, ho sa tsotelehe boholo, e lokeloa ke tlhokomelo ea rona le boiteko ba rona. Bareki ba rona ba bangata, ba thabileng le ba khotsofetseng ba tla tiisa habonolo polelong ena.

4. Leano la boleng

Hyluo e ikemiselitse ho ntlafatsa ts'ebetso e tsoelang pele ea sistimi ea eona ea boleng le ho phethela khotsofalo ea bareki, joalo ka ho hlalosoa ka kotloloho ka ho fihlela:

Sehlahisoa se entsoeng ka mokhoa o sireletsehileng ka har'a maele a boletsoeng a moreki.

Sehlahisoa se entsoeng ka mokhoa o sireletsehileng ka har'a maele a boletsoeng a moreki.

Ho tsamaisa kapa ho feta litebello tsa moreki.

Ho tsamaisa kapa ho feta litebello tsa moreki.

Tlhokomelo ea motho ho qoqa ho tsohle le moreki.

Tlhokomelo ea motho ho qoqa ho tsohle le moreki.

Boinehelo ba rona ho Bopaki bo phahameng ka ho fetisisa le ho tsoa ha nako e ngata bo sebeletsa likhoebo tse ngata tse nyarosang tsa CNC.